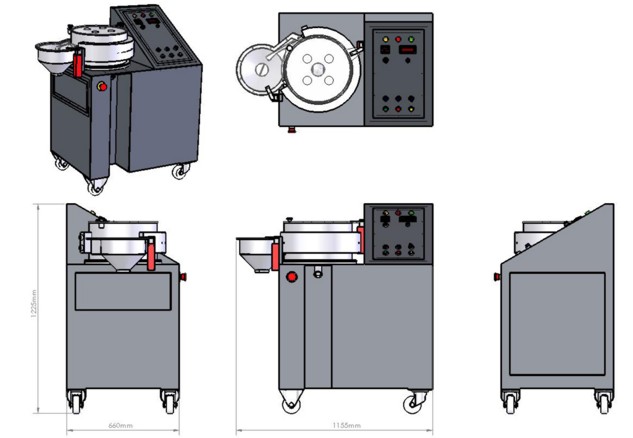

A Production or Pilot Plant Spheronizer for Spheronizing Pharmaceutical Compounds

The Spheronizer 380 is a floor standing production Spheronizer that can be customized to your requirements. This model is designed for large scale experimental use and small quantity batch production. It is small enough to be moved on the fitted castors yet sturdy enough to be considered as production equipment. It is designed to work as companion equipment with the Caleva 40 gear extruder or Caleva 35 screen extruder.

The Spheronizer 380 is a robust, mobile and very practically sized small production machine that is also often used for larger scale development trials as well as smaller scale production.

The front panel has all the main controls. The spheronizer disc is driven by an AC motor with an inverter. Disc speed is controlled by an analog potentiometer with digital speed display in RPM. There is also an optional PLC control available allowing up to 10 preset disc speeds. The machine uses an electronic timer with push button controls or a PLC to set spheronization time and product discharge. The automatic mode allows user-defined processing times, and an Manual/Auto changeover switch is provided to allow the user to override the automatic timer control, if necessary. The optional PLC controls allows the user to set time points as well as set the speed of the spheronizer at specific time points.

The spheronizer 380 is supplied with a spheronizing disc with 6mm square pitch cross hatch as standard. Other types of discs are available.

The operator is protected from all moving parts by safety interlocks and is designed in accordance with GMP guidelines.

The Spheronizer 380 is one of a comprehensive range of extruders and Spheronizers offered by Caleva.

Features

- Designed for the production of smooth, regular spheroids.

- A robust production machine small enough for development work.

- Compact size that is easily transportable between locations.

- Convenient batch size from 0.5kg to 4kg.

- Spheroid or pellet production can be greater than 40kg per hour.

- A full range of options available including fully automatic operation.

- Contact parts in 316 stainless steel, Cabinet in 304 Stainless Steel.

- Designed for the pharmaceutical industry.

- Main seal area fitted with compressed air inlet to minimize ingress of dust

- Quickly detachable main product discharge chute.

- GMP design

- Special features to meet individual requirements

Options

There are a number of options available to suit the requirements of your application. Please discuss your project with us so we can determine which options are suitable for you.

The options available are:

- Fines Air system for dusty products, to eliminate dust falling between the disc and the drum.

- Alternative types of Spheronizing disks (cross hatch and radial patterns).

- FDA approved anti-stick coatings for drums and disks.

- Drum heating/cooling jacket.

- PLC controls and monitoring.

- Material certs for product contact surfaces.

- A data aquisition package to monitor and record operating parameters during spheronization is available.

- Loading hopper interlinked with machine controls or mounted on load cells providing measured weight into Spheronizer drum.

- Explosion-proof design.

- The level of automation can be supplied to suit your specific requirements.

Specs

| Loading: | Manual |

| Overall Dimensions: | 950 mm W x 700 mm D x 1,150 mm H |

| Weight: | 360 Kg |

| Cabinet: | Grained 304 SS |

| Contact Parts: | 316 SS, food-grade plastic, and Acrylic |

| Controls: | Front Mounted including: Electronic speed control by means of ten (10) turn potentiometer with LED digital RPM display, Power/Motor ON indicator lights, START/STOP push button, and emergency E-STOP push button. |

| Manual and Automatic Operation: | Electronic timer and pushbutton controls for spheronization time and product discharge. Automatic mode permits the operator-defined process times. Auto/Manual selector for timer control when required. |

| Extrudate Load: | 2-4 kg per batch |

| Cycle Time: | Approx. 4 min./batch |

| Processing Capacity: | 30-40 Kg/hour, depending upon the properties of the product and cycle time. |

| Disc Speed: | 400-1500 RPM |

| Motor: | 2.2 Kw |

| Utilities: | Electric: 230-460V 3PH; 5-6 Bar compressed air |

| Documentation: | Installation/Operation Manual |

| Specifications may be subject to change without notice. | |

Videos

There are no videos for this product.