The New Caleva Multi-Lab Combines Mixing, Extrusion and Spheronization Functions into One Bench Top Unit

Using interchangeable attachments, the new Caleva Multi-Lab combines Mixing, Extrusion and Spheronization functions into one small bench top unit. The Caleva Multi-Lab is a new R&D tool for laboratories that have to Mix, Extrude and Spheronize (pelletize) very small quantities of material. The instrument is capable of producing batches ranging from 15 to 50 grams, with an effective yield of approximately 90%.

A typical mixing-extrusion-spheronization run is as follows:

- The mixing bowl, which is basically a very small high shear mixer-granulator, is attached to the base unit containing the drive, controls and safety interlocks. The dry powder is than weighed and added to the mixing bowl and the safety cover put in place. The mixer is started and liquid binder is added during mixing until the resulting wet mass of the desired consistency is produced.

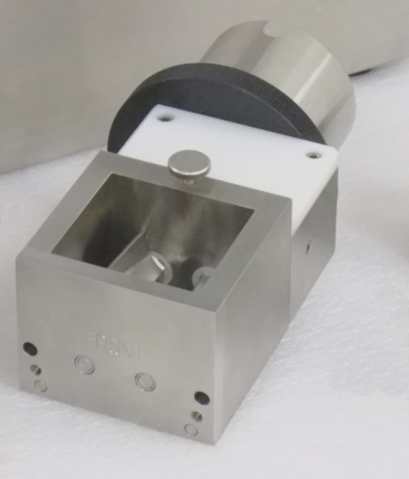

- The mixing bowl is removed and the screw extruder and safety cover is attached to the base unit. The wet mass produced during the mixing step is fed into the extruder until the batch is completely extruded.

- The Extruder is removed and the Spheronizer bowl is attached to the base unit. After the extrudate is added to Spheronizer bowl and the safety cover is attached, the unit is run (typically about 1-2 minutes) until all of the extrudate is converted into pellets approximately the same diameter as the extrudate.

The Caleva Multi Lab is very simple to operate and all of the attachments are added and removed without needing any tools. Using the Caleva Multi-Lab, it typically, it takes about 30 minutes to convert powder into high quality spheroids.The Caleva Multi-Lab is ideal for:

- Basic research

- Pharmaceutical formulation development

- Industrial and government research

- University teaching

Features

- High shear Mixer-Granulator, Extruder and Spheronizer in one small, bench top unit.

- Batch sizes from 15 to 50 grams.

- Easy to operate. No steep learning curve involved.

- Cost effective for your budget.

- Create high quality spheres in just a few minutes.

- Mixing bowl, Extruder and Spheronizer speeds variable by operator.

- No tools required. No tools to lose.

- Excellent, high quality product with very little waste.

- Granulator bowl, Extruder and Spheronizer bowl sized and designed to work together.

- Additional attachments for sieving, delumping and blending will also be available in the near future.

- Used in conjunction with the Caleva Mini Coater Dryer you can go from dry powder to coated beads using only two machines in under two hours.

Options

- IQ/OQ documents

- Material specs for product contact surfaces

- Half sized mixer bowl for small quantities

- Extruder dies with different hole diameters (1mm is standard) and configurations.

- 316 SS Spheronizer disc 1mm x 1mm square pitch (3mm x 3 mm disc supplied as standard)

- 316 SS Spheronizer disc radial groove pattern

- Heating/Cooling Jacket for full or half mixing bowl

- Installation and training services

Specs

| Size (approx.): | 58x58x36 cm (depending on attachments fitted and options supplied) |

| Weight (approx.): | 39 to 45 kg (depending on attachments fitted and options supplied) |

| Cabinet: | 304 brushed SS |

| Contact Parts: | 316 SS and Acetal POM |

| Motor Power: | 220W AC motor driven by inverter |

| Controls: | Speed set by non-calibrated potentiometer, digital speed readout in RPM, START button, STOP button, emergency stop button, POWER ON indicator, MOTOR ON indicator, automatic timer. Power is supplied by a standard plug and socket connector. Single phase 115/240 VAC according to user requirement. |

| Output: | From 10-50g depending on attachment, density and characteristics of the material being processed. |

| Product Feed: | Manual |

| Supplied as Standard: | If purchased, the Mixer Attachment consists of 316 SS full size bowl with paddles, gearbox, syringe and safety covers; If purchased, the Extruder Attachment consists of 316 SS extruder body, screw, die with 1mm deep by 1mm ∅ holes, safety cover, product feed tray, and Delrin scraper/pusher tool; If purchased, the Spheronizer Attachment consists of 85mm ∅ 316 SS Spheronizing bowl with 3mm x 3mm square pitch Spheronizing disc and safety cover |

| Safety: | Designed to the highest safety standards. All attachments are supplied with safety covers. The machine cannot be operated if all the safety covers are not in place. |

| Specifications may be subject to change without notice. | |

Videos

If you have trouble viewing the video clip in your browser, you can view or download (right click and “Save Link As” or “Save Target As”) the MP4 versions of the Caleva Multi-Lab video clip.