A Benchtop Extruder with Variable Die Diameter and Depth with Both Radial and Axial Extrusion

Only the Caleva Variable Density Extruder ® (VDE ®)can offer a selection of extruder die apertures and bore lengths for both radial and axial extrusion methods.

With aperture diameters from 0.2-2.0mm, and bore lengths from 0.2-12.0mm, the optimal length to diameter ratio (L:D ratio) can be selected to produce the ideal density extrusions to suit your application.

The extruder can be purchased with radial, axial or both configurations. The equipment can be upgraded later according to need.

The unique ability of the VDE ® to produce extrusions using either the Axial or Radial methods, coupled with the range of die L:D ratios allows for quick and easy laboratory evaluation of various densities and formulations. There is nothing else available that offers this degree of flexibility and ease of use in a single piece of equipment.

The VDE ® from Caleva, for the development of pellets by Extrusion and Spheronization. The most flexible and productive laboratory extruder available. The only bench-top extruder with variable die diameter and depth with both radial and axial extrusion!

Features

- Radial and axial extrusion in a single bench-top unit.

- Ability to control the density of the extrudate.

- High degree of flexibility to meet formulation requirements.

- A wide range of apertures and depths are available.

- Suitable for most low pressure wet extrusion processes.

- Assemble and disassemble extruder head without tools.

- Product can be heated or cooled as required.

- A water jacket is standard on all configurations.

- All contact parts in 316 stainless steel, FDA approved plastic

- Cabinet in brushed 304 stainless steel.

Options

There are a number of options available to suit your application. Feel free to call us so we can determine which options are suitable for you.

The options available are:

- Additional radial screens with holes from 0.2-2.0mm ⌀ x 0.5-3.5mm deep.

- Additional axial dies with holes from 0.2-2.0mm ⌀ x 12mm deep.

- Data acquisition package.

- Training.

- Material certificates for product contact surfaces.

- IQ OQ Document Package.

Specs

| Loading: | Manual, with feed tray positioned above inlet. |

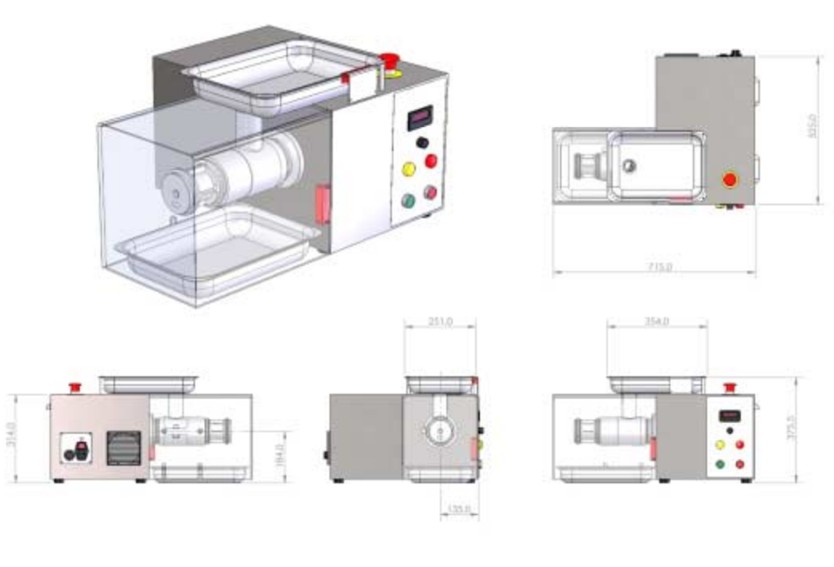

| Overall Dimensions (cm): | 72w x 43d x 37h |

| Weight: | 42 Kg |

| Cabinet: | Grained 304 SS |

| Contact Parts: | 316 SS, food-grade plastic |

| Controls: | RPM display; speed adjustment dial; Interlocks, & running lights;Power ON/OFF, Start/Stop, Reset, & E-Stop buttons. |

| Processing Capacity: | Radial ≅ 27kg/hr, Axial ≅ 20kg/hr (product dependent) |

| Motor Speed: | 10-90 RPM |

| Standard Apertures: | Axial Die: 1mm ⌀ x 1mm deep. Radial Screen: 1mm ⌀ x 1mm deep. |

| Motor: | 750 W |

| Utilities: | Electric: 120 VAC 60 Hz, or to customer's requirements; Water for jacket. |

| Documentation: | Installation/Operation Manual |

Specifications may be subject to change without notice. Please contact us for configuration advice. |

|

Videos

If you have trouble viewing the video clip in your browser, you can view or download (right click and “Save Link As” or “Save Target As”) the MP4 versions of the Caleva Variable Density Extruder video clip.